- Technical Service Bulletin #612: T-5 input to mainshaft bearing upgrade… 01DEC00

- A joint venture between John Pearson and Chris Neighbors…

| I would like to take a moment to personally thank John Pearson for doing the hard part of this upgrade: the actual work! I managed to gather what I thought was sufficient information, but John brought forth a considerable volume of important information…Thanks for the effort, and sharing, John! |

Scope: The venerable T5 has gone through many changes since it’s inception, trying to keep up with the ever increasing torque output of the Mustang in stock form (let alone 'enhanced'!). One of the last changes made to the T5 was to replace the potentially troublesome and cumbersome loose roller bearings, shims, and roller thrust bearing interface between the input and mainshaft with a single tapered roller bearing. This allows higher bearing preload, and subsequently less input shaft deflection and possible angularity issues. Retrofitting the tapered roller appears to be quite simple, if you have access to a machine shop, an understanding of T5 repair, and a few hours free time…It also allows the reclamation of previously damaged and unusable mainshafts, while increasing capacity! If the idea of attempting this yourself isn't appealing, Bob Hanlon offers a 'kit' that includes a modified mainshaft and new input for about $400…

- Required components:

Bearing: Timken Set 1 or equivalent (CR BR1, Federal Mogul A1) [Autozone: $6.99]

Cup: LM11710 Cone: LM11749 - Input shaft: '93 Cobra, Tremec part number 1352-085-050

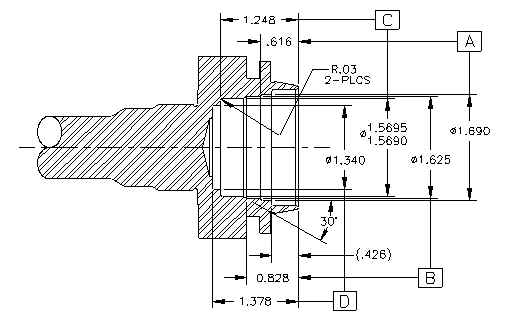

- Mainshaft: modified per drawing below

- Input bearing shims, variety

Vendor

Phone

Fax

Website

National Drivetrain

(800) 507-4327

(773) 376-9135

D&D Performance

(248) 926-6220

na

na

Hanlon Motorsports

(610) 469-2695

(610) 469-2694

na

Procedure:

A word of caution before proceeding: The T5-Z and Cobra T5’s (all with the tapered roller bearing) use a retaining ring to keep the 3-4 synchro hub in location on the mainshaft. The non-Z/Cobra trannys restrict movement with the stack-up of the roller thrust bearing and shim (between the hub and input bearing). The length of splined shaft protruding beyond the synchro hub is shorter on the non-Z/Cobra T5's, and therefore prevents the ability to install a retaining or snap ring. I'm a bit nervous about this, but all of the hubs I've removed were nearly pressed on, and required some effort to remove them. A groove could be cut in the shaft for a smaller ID ring, but the reduction in cross-sectional area is very detrimental, especially coupled with the stress concentration (although very little torsion is present; mainly a bending moment). I hate to recommend Loc-tite bearing retainer, as it will make future service nigh impossible without heat…[other options might be available: staking, peening, swedging, deforming one spline to create slight interference…] Also, since the bearing is larger diameter than the ID of the synchro hub and will not pass through it, the bearing will have to be removed in order to remove the hub. A small bearing separator will be required…[The Pearson Spacer is born! Details pending…]

Trans disassembly: Disassemble the transmission per the Tremec or Helms manual, Hanlon’s video, or my previous literary work (LOL!). Remove the pressed on tapered roller bearing from the front of the input shaft and clean (carb cleaner works wonders!). Sight down the input shaft splines, checking for straightness [Oftentimes, a car that has been launched on slicks will tend to ‘twist’ the splines]. If the twist is slight, very closely inspect (better yet, magnaflux or Zyglo) the end of the splines towards the body for cracks. If your particular input is severely twisted or cracked, replacement is suggested. Remove the mainshaft assembly and disassemble down to the bare shaft (make sure you keep the parts in order); clean.

Machine (er, 'grind') shop work: Cart the mainshaft (and input, if brave!) to your ‘favorite’ local grinder (e.g. crank grinders), with a copy of the drawing(s) below. Smile, act civil, and try not to grimace when you are quoted a price. Keep in mind these guys make money with a running machine, and setting up a new part takes time. Expect to pay in the $25 to $35 range to get the mainshaft ground (who knows what on the input!).

Mainshaft: Chuck up the mainshaft in the lathe, and set TIR to be .001" or less, as above. Machine the features as indicated below, to provide .0005" to .001" bearing interference.

Note: I had originally detailed the mainshaft using the .620" dimension only, but some variation in the end of the shaft caused a measurement plane concern (up to .008" variation recorded). Please use the 1.012" dim, as indicted…(I left the .620" as a reference dim.)]

Input shaft: Because the input shaft is hardened, machining the required features is nigh impossible. Grinding is about the only realistic modification option, but may prove too costly. It is recommended that you purchase the correct input shaft new. The correct input is from the '93 Cobra T5 (build code 1352-218); Tremec apart number 1352-085-050. You cannot use the 2.95 first-geared Z-spec input, as it has 24-teeth versus the 23 on the 3.35 first gear transmissions. National Drivetrain has this shaft available for $125. [I will leave the following verbiage intact, in the event that some of you are gluttons for punishment or have access to the proper grinding equipment…]

- Chuck the input shaft up in the grinder (preferably at the bearing surface, to shorten the ‘overhang’. Be careful to avoid damage to the bearing surface) and set the total indicator run-out (TIR) to .001" or less. While this sounds ‘tight’, keep in mind that a part with a similar tolerance will be mated with it, creating .002" maximum eccentricity. Machine the input to the dimensions below, which will provide .0005" to .001" interference fit on the bearing cup (race). While not indicated, shoot for a 32 microinch or better finish on the race seat features…

- [Note: the factory inputs do not provide a clearance feature to facilitate race removal in the event of damage. A small three-jaw internal (bearing) puller might allow removal, but I cannot confirm that at this point. If you have the means, two or three small milled slots just below the race seat (in the 1.340 diameter feature) will allow a two- or three-jaw puller to get under the race, allowing removal…Tech tip from Paul Rebold: If you have a bearing race that is installed in a blind recess and it absolutely, positively must be removed, run a bead of weld around on the race where the bearing contacts and it will fall out everytime. Of course you need a new race, but...]

| Feature | Diameter | Depth | Purpose |

| A | 1.690 | .616 | ??? (can be eliminated...) |

| B | 1.625 | .828 | Bearing race (cup) clearance |

| C | 1.5695/1.5690 | 1.248 | Bearing race (cup) seat |

| D | 1.340 | 1.378 | Bearing cage clearance |

Assembly:

Upon receipt of your freshly machined parts, clean them with an appropriate cleaner and air dry. Lube the OD of the bearing race and press into the input shaft, making sure it seats in the bore [place the race in the freezer for a period of time (thirty minutes or so…) prior to assembly, for easier assembly]. Assemble the mainshaft (at least from the first and second gear synchro hub forward), and press the bearing onto the ‘nose’ of the mainshaft, making sure it is seated. Assemble the remainder of the trans per appropriate documentation and/or procedures…until you get to:

Endplay set-up: One of the main advantages of the tapered roller bearing is the ability to set the input bearing preload higher than with the flat roller thrust bearing. Following the Helm manual, install the input shaft (with bearing pressed on) and input bearing race in the retainer (without any shims), and tighten the four fasteners. Place the transmission on the face of the case, with the input shaft facing down, and tailhousing up [I used a couple of heads to set mine on, as they were handy]. Set up a dial indicator so that it contacts the end of the output shaft (see figure, right), and zero the dial. Using a block of wood, push upward on the input shaft, and note the reading on the dial indicator. Normally, the indicator reading would be the optimum shim, but with the tapered roller bearing, add .0005" to .004" (Thanks to Glenn Forester for confirmation!) for proper preload. Rotate the trans back to horizontal, remove the retainer, install appropriate shims, apply a bead of RTV to the retainer, and install.

John's shim story (slightly edited):

I needed a .035" shim and found it more difficult to find than I thought. I had a .030" and a .010". I found an easy way to lap the shims. I lapped the .030 to .025 in no time after I got the technique down. I had a piece of Melamine, a plastic coated particle board, about 16x16". I cut a corner off a little bigger than the shim. Then I traced the inside of the shim onto a piece of .010" sheet steel (CN: shim stock might work…), cut the steel 'dot' out a little smaller, and glued it to the small corner of Melamine I had cut. I used this to hold and move the shim down on the sandpaper. I then placed a full sheet of wet/dry 320 grit onto the large piece of Melamine, wetted the paper with paint thinner, and placed the shim on the paper. I placed the small piece of Malinine, with steel dot glued on, over the shim and wiggled it around to catch the shim. I ran the shim across the full width of the paper at one end about 100 times as I turned the shim every 10 times or so (CN: I usually use a figure eight (8) pattern…). I kept moving across the sandpaper as one 'track' would wear out. I got 4 tracks across a sheet. It took two (2) sheets of sandpaper and about 15 minutes to knock .005" off my shim.

I wasn't having any luck lapping the shim until I did it this way. Not bad if you are in a pinch, or you want to really get close with your shims… Alright John!

Note: All the layouts were done in AutoCAD Version 14. If you would like an electronic copy, drop me a line, and I’ll get it out to you ASAP…

Cost breakdown: (from John's experience…)

'93 Cobra Input shaft $125.00 Shipping & handling 9.00 Bearing 7.95 Machining the main shaft 25.00 Pressing cup into input shaft 5.00 Total:

$171.95

References:

http://www.blarg.net/~bossbill/t_5.html (good T5 info!)

Updates:

21SEP00: corrected preload numbers per Glenn Forester added race removal tip per Paul Rebold

01DEC00: added John's info; rewrote and corrected!

- Good luck! Chris Neighbors

- caneighbors@hotmail.com